Aiming for practical use in 2028

🟦 Intel is also participating! Establishment of a research association to automate semiconductor back-end processes

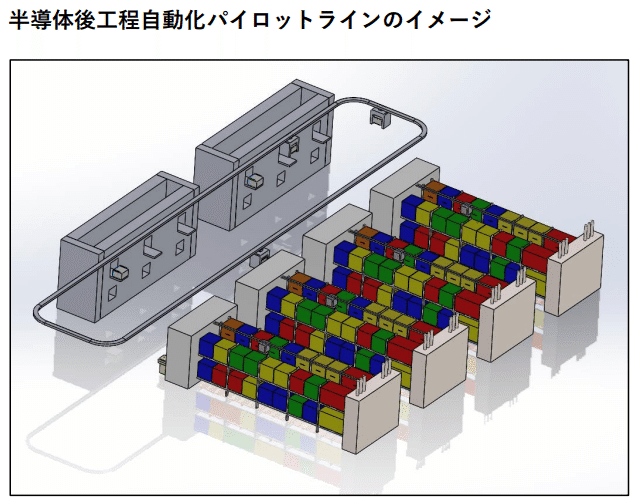

Fifteen companies and organizations, including Intel, Omron, and Yamaha Motor, have established SATAS, a technology research association that aims to automate and standardize the “back-end process” of semiconductor manufacturing. With the aim of commercialization by 2028, we will develop the technologies and equipment necessary for back-end processing, build a demonstration line, and standardize it. Technologies to be researched and developed include transport robots, automated inspection equipment, and sealing equipment. The demonstration line is scheduled to be installed in Japan by the end of 2028.

“Post-process” of semiconductor manufacturing

Semiconductor manufacturing is divided into front-end and back-end processes. The front-end process is the process of forming a precise circuit on a silicon crystal (wafer). The post-process is a process in which the wafer is cut out, processed into small parts called chips, and mounted on a substrate to make the final product. The process of inspecting and packaging.

The back-end process consists mainly of the following tasks:

- Dicing: Cutting wafers into individual chips

- Bonding: Connecting the chip and the substrate with a thin gold wire

- Mold: Cover and protect the chip and substrate with resin

- Inspection: Inspect the functionality and performance of the finished product

🟦 To promote the transfer of production to Japan for back-end processes

In recent years, the importance of back-end processes has increased in semiconductor manufacturing. The miniaturization technology of the front-end process is approaching its physical limit, and technological innovation in the back-end process is essential to improve performance. In order to promote the relocation of production at back-end processing factories that have been concentrated in China, there is an urgent need to automate back-end processes in Japan and the U.S., where labor costs are high. Japan’s semiconductor industry has high technological capabilities in the fields of equipment and materials required for back-end processes.

Main companies participating in the research union

- Intel

- Yamaha Motor

- OMRON

- sharp

- Toshiba

- Resonac Holdings

- Shin-Etsu Chemical

🟦Summary

15 companies and organizations participate in the automation and standardization of “back-end processes” in semiconductor manufacturing! Aiming for practical application in 2028, we are striving to strengthen domestic supply chains and develop high-value-added industries that leverage Japan’s strengths

Intel’s focus on advanced back-end technology is a very interesting development. Technologies such as UCIe (Universal Chiplet Interconnect Express) and glass interposers have the potential to revolutionize chiplets.